Industry standard test procedures help issuers achieve the ultimate ’10-year credential'

18 January, 2016

category: Contactless, Corporate, Financial, Government, Smart Cards

Standardizing card durability

There are several facets to card durability. A primary consideration is the mechanical durability of the card body, which includes characteristics like bending and stiffness, peel strength and resistance to chemicals, says Brad McGoran, principal engineer at Exponent, a consultancy that performs card testing.

Additionally, there are the durability characteristics of the printed and laminated features on the card. These include the abrasion resistance of the magnetic stripe or printed barcode, the resistance of the printed dye to smear or drift, and the UV resistance of the printed surface, McGoran explains.

If the card includes an integrated circuit chip with a contact pad or a contactless antenna, durability issues also revolve around the resilience of those features. For example, the card should maintain functionality after exposure to x-rays and magnetic fields, and it should survive anticipated levels of electrostatic discharge exposure.

For each of these areas, internationally recognized standards bodies have developed a series of testing methods. Test labs implement these prescribed procedures to provide unbiased analysis of a specific card construction’s durability and likely longevity. Key test standards include ISO 24789 and ANSI 322.

ISO/IEC 24789: This standard is made up of two parts. The first is a methodology for determining a card’s expected lifespan taking into consideration the demands placed upon it by the various applications it will support. The second part uses this determination to define a series of tests to evaluate if it can meet this prescribed lifespan.

Think of it this way, the demands on a passport card used infrequently for international travel are far less than those placed on a fare collection card used multiple times each day for public transport. Still the required lifespan for a passport card is far longer than that of a transit card, so this too must be taken into consideration as tests are designed.

ANSI INCITS 322: This defines a Card Structural Integrity Test to help gauge a card’s resilience against delamination under adverse environmental conditions. The test is considered rigorous or extreme, and used most often as a qualitative or comparative assessment between different card constructions.

To conduct one of the ANSI INCITS 322 tests, cards are placed into a one-gallon paint can along with “dummy cards.” Thirty-milliliters of distilled water and 10 grams of sand are added, and the can is sealed and mounted into a standard paint shaker similar to the machines used at hardware stores. The cards are then shaken for three hours, removed and rinsed. The cards are generally considered satisfactory if they do not delaminate or peel apart. If they include an integrated circuit chip, this should still be functional.

This test has proven to be quite revealing for the various card materials and structure technologies used by card manufacturers. Many cards come out of the shaker with only worn corners, but some cards simply disintegrate or separate into their component layers.

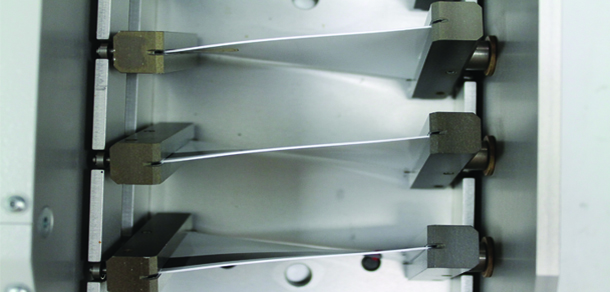

ANSI INCITS 322 Surface Abrasion Test

To conduct the Surface Abrasion Test, two cards are mounted on a machine that rotates them below a pair of abrading wheels or grinders of prescribed weight and grit rating. The machine is stopped every 250 rotations and a resurfacing disk with a prescribed grit rating is used to resurface the abrasion wheels. After every 500 cycles the cards are photo documented. This process continues until the cards reach 5,000 cycles. The estimated point of print breakthrough is tracked and recorded.

A card issuer caveat emptor

When it comes right down to it an issuer has to look at the use of the credential. “In our experience, there is no one single formula for the best and most durable card body construction since different blends and formulations are best suited to different environments and usage scenarios,” McGoran says. “We recommend that issuers and their card manufacturers run specific tests to evaluate overall durability of the card body to ensure that fielded cards meet their designated life expectation.”