The three pillars of a secure ID: card materials, personalization and Issuance models

04 November, 2015

category: Corporate, Financial, Government, Smart Cards

Central issuance

In a central issuance scenario, the type of card materials drives the specifics of the personalization process.

Regardless of the material choice, the first round of personalization is typically done on large sheets, for example 18-inch by 12-inch sheets that will ultimately be die cut to produce 21 finished cards. These sheets are fed into a printer to apply fixed graphics such as static background images and other standard security features such as guilloche printing or micro text.

In some cases, personalized data – name, ID number, date of birth, photo – is applied at the same time. More often, however, such as when using synthetic materials like Teslin substrate, variable data is added in the separate process using inket or laser printer technology.

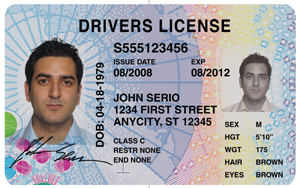

Many states in the U.S. are using Teslin and central issuance for driver licenses, Jones explains. “The personalized information is laser printed on the Teslin substrate and other security features are layered on top of that, sometimes including laser engraving,” he says.

When polycarbonate is personalized, the variable data is added later in the process using a laser engraver, often after the cards have been die cut from the larger sheet. Such is the case with the U.S. passport card, a polycarbonate ID that is personalized 100% via laser engraving, says Jones.

If contactless chip and antennae are to be used, they are often combined in an inlay that is added as one of the unique layers that in the large sheet. If however, contact chips are included, the integrated circuits are normally embedded after dye cutting.

Regardless of the specific steps described above, in the end the finished sheet is laminated and each single card die cut from the larger sheet. Finally, these individual cards are encoded and tested.

Over-the-counter issuance

In an over-the-counter issuance model everything is done while the customer waits, and they walk out of the office with a finished ID. Instead of working with large sheets, each facility receives card blanks, which often have certain security features already embedded.

The same card materials used in central issuance environments can also be issued over the counter. Most often, however, decentralized issuance models make use of more common dye sublimation or retransfer ID card printers.

With Teslin or other composite cards, the personalized data is most often printed on an outer card layer via dye sublimation or printed on a clear overlay via retransfer. Next, a final polycarbonate or polyester overlay helps to protect the card and the information, explains Scaglia.

In other cases, the Teslin substrate can be personalized using inkjet or laser printing and then thermal sealed in a secure layer prior to final lamination. “When you personalize on Teslin substrate and then overlaminate, you have multiple layers of security and the personalization is embedded into the card,” he explains.

Polycarbonate cards can be issued over the counter as well, but in order to take advantage of laser engraving issuers would need to deploy numerous desktop laser engravers. These card printers are significantly more expensive than traditional ID card printers, but they do enable some degree cost savings, for example, by eliminating ribbons.

Still, deploying a significant volume of expensive issuance systems across a large geographic area can quickly become costly and challenging to manage.

Conclusion

Choice is a good thing, and when it comes to secure card production, choices abound. The choice of card materials, personalization technology and issuance models each is crucial to a secure issuance, and each has impacts on the others. When properly evaluated, selected and deployed, these three pillars of secure ID issuance can work together to build a strong, fraud-resistant foundation.